A FOOD SAFETY CHALLENGE

A FOOD SAFETY CHALLENGE

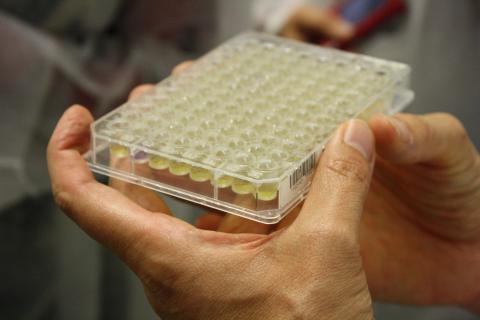

Guaranteeing product safety

Food safety management starts on the farm before continuing in factories and during transportation. It is then maintained in stores and consumers’ homes.

A SHARED CHALLENGE

A SHARED CHALLENGE

Maintaining the positive image of dairy products

The slightest food safety issue can have a negative impact on the entire dairy industry. Dairy professionals therefore work together to manage the safety of dairy products.

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,… All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.