Diversity, quality and taste

Diversity, quality and taste

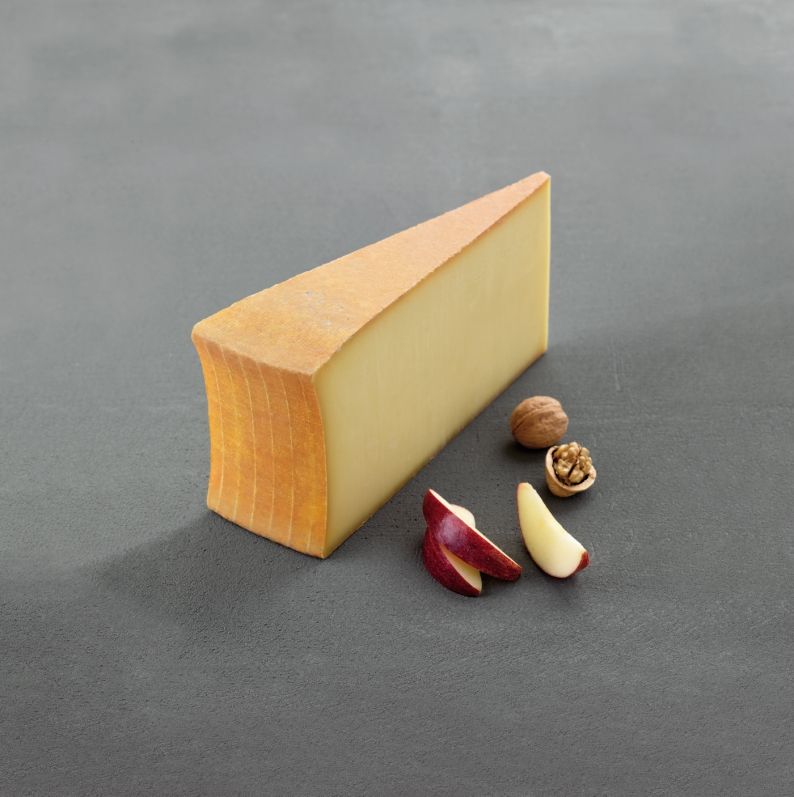

Diversity : France boasts 1,200 varieties of cheese. These are divided into different types, which are linked to the distinctive features of their regions of origin, including the climate, soil and undersoil. There are therefore many different types of land, as well as farms and farming traditions.

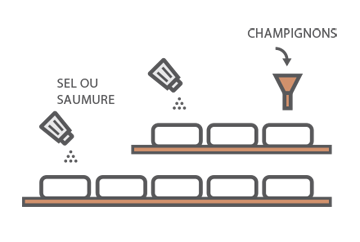

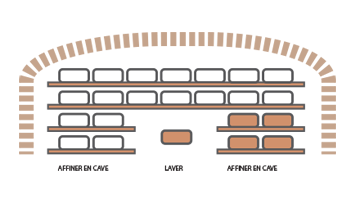

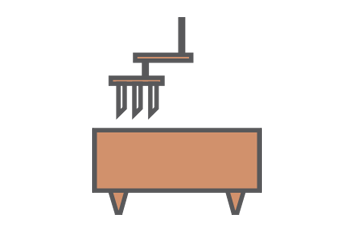

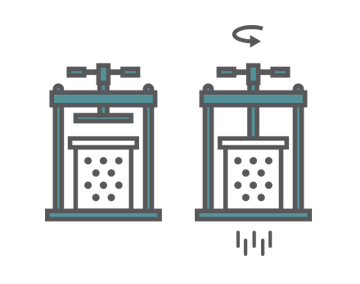

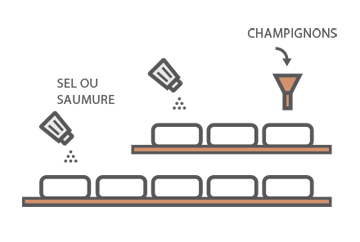

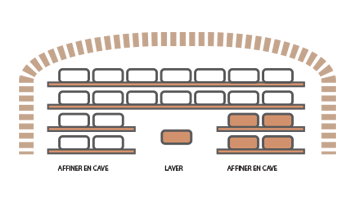

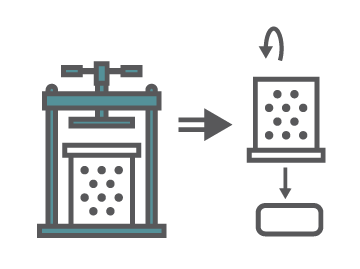

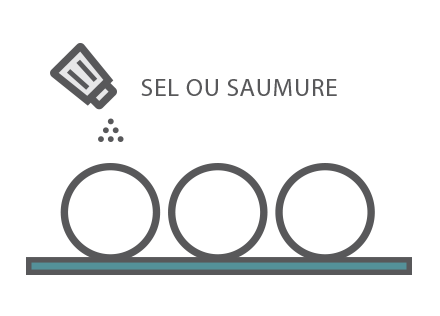

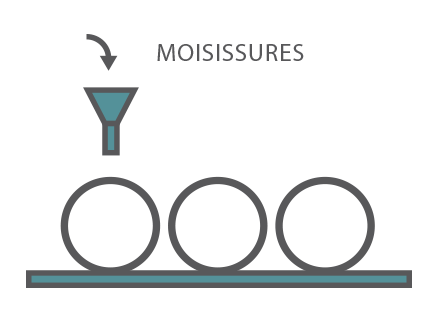

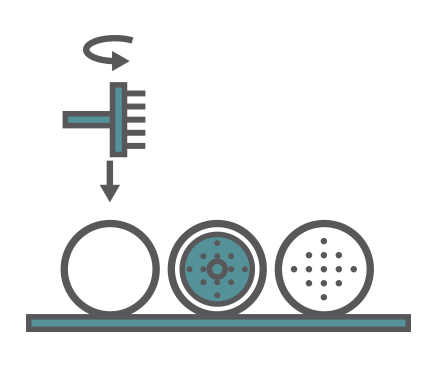

Quality : This comes from experience, expertise and technique, handed down from generation to generation and enhanced over time.

Taste : Each cheese has its own distinctive smell, flavour and texture resulting from a particular region or maturation period.

These cheeses tell a story about geography, people and landscapes!

In 2012, the French were the world’s leading consumers of cheese at 26.2 kg/inhabitant/year.

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,… All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.