Schéma compo lait - ANG

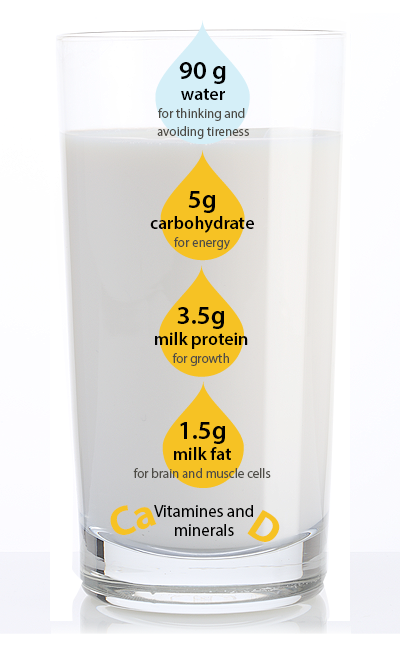

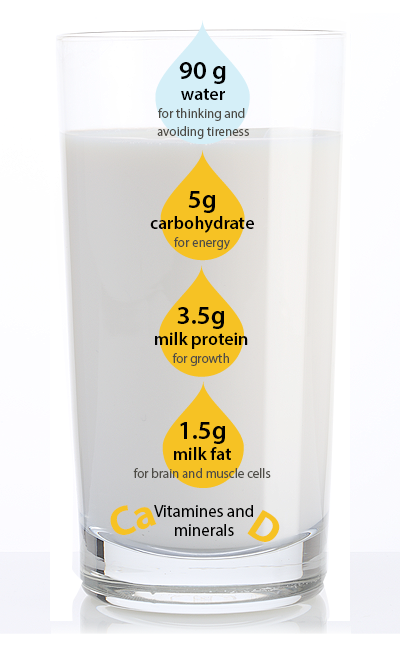

What’s in a 100 ml glass of semi-skimmed milk?

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…Dairy Products website

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…Dairy Products website

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.Cniel Infos website

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.Cniel Infos website

Monks in the Middle Ages and industrial processors in the present day have all shared the same processing methods and challenges: managing the natural rhythm of milk’s metamorphoses, ensuring product quality and safety, and providing consumers with ever more guarantees.

What’s in a 100 ml glass of semi-skimmed milk?

Milk in different states

The main ingredients of milk are present in three different physical states:

Milk appears white thanks to casein (a dominant protein in milk) and fat. These two ingredients reflect light, which is why milk is white.

But sometimes milk can have a hint of blue! Skimmed milk contains less fat and therefore fewer light-reflecting particles. Casein refracts more blue waves, which is why we see a hint of blue in skimmed milk.

Milk produces a wide variety of dairy products, thanks to its rich ingredients, as well biological and physical processing methods.

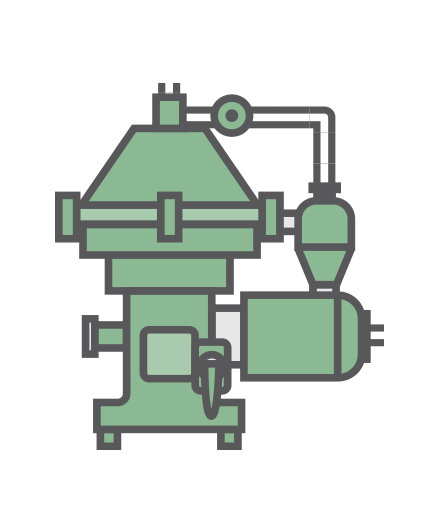

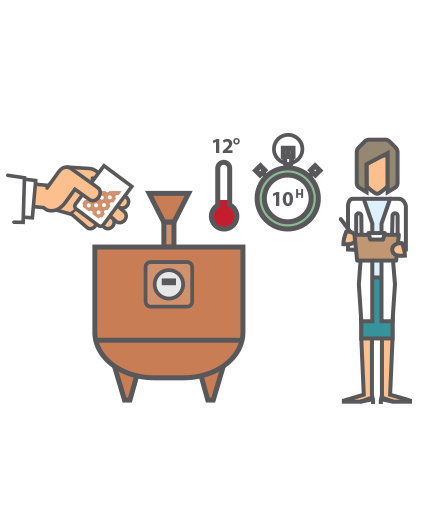

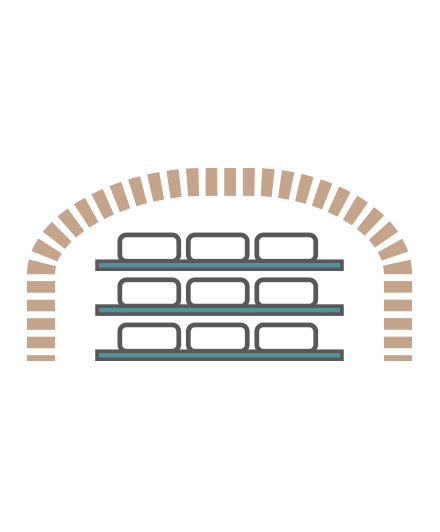

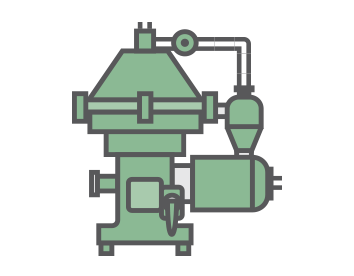

Previous dairy methods have been conserved and optimized with the latest technology to offer ever more quality and guarantees.

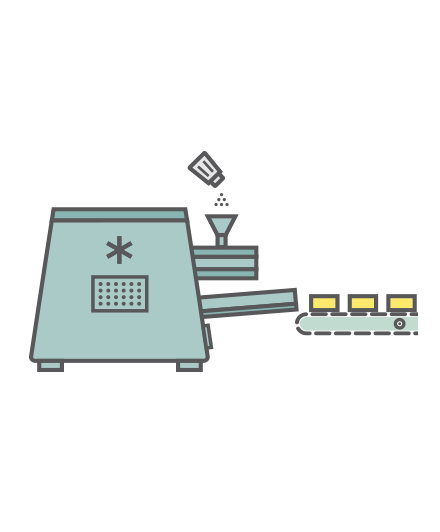

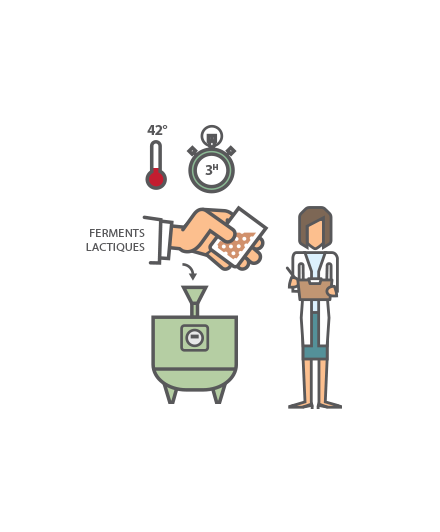

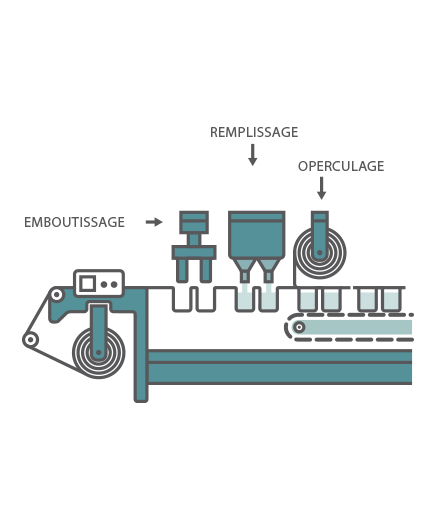

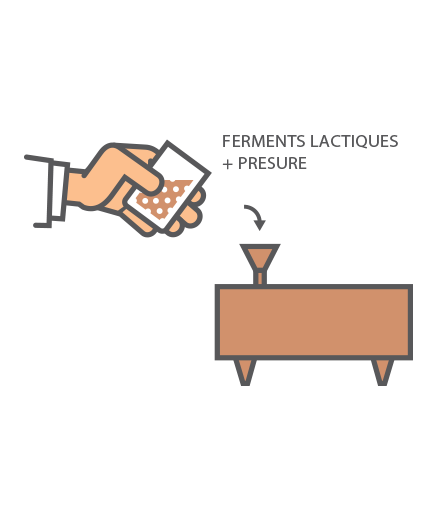

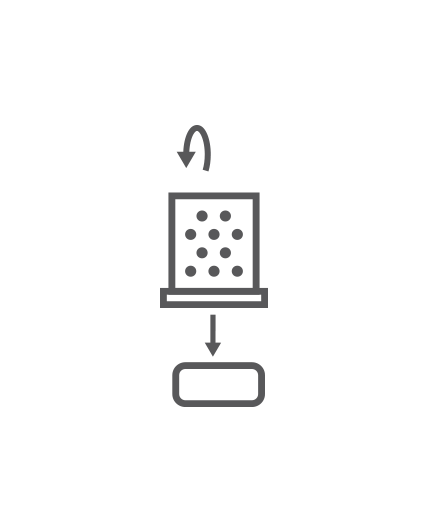

2 types of processing methods

Features of quality milk

Standard composition of milk

Farmers: the first guarantors of milk quality

Farmers attend to the health and diet of their herds while ensuring spotless hygiene. These commitments are set out in the French Charter for Good Agricultural Practices. Some 90% of French cattle farmers have adopted this code. The price farmers receive for their milk also depends on quality.

Milk collection is rigorously organized

The milking shed and equipment are disinfected after each milking session. Milk is stored in a tank at 4°C to respect the cold chain, then transported in refrigerated lorries. Milk quality is controlled randomly at least three times a month in certified laboratories.

Milk is controlled again after arriving at the dairy

Milk samples are analysed. The milk undergoes physical treatments to eliminate micro-organisms. Traceability is ensured between the tank and the farms. No dairy product leaves the dairy without a quality guarantee.

Find out more...

On the farm, the application of the French Charter for Good Agricultural Practices is controlled to ensure correct animal feeding, perfect hygiene, etc. Farmers are also assisted by veterinarians, who monitor animal health.

Cow’s milk is subject to rigorous controls. During milking, numerous samples are taken and analysed in a laboratory to ensure food safety. Upon arrival at the factory, milk is tested again as it is transferred from the tanker to the factory’s storage tank.

To avoid altering milk quality during processing, the factory uses the Hazard Analysis and Critical Control Points (HACCP) method. This involves identifying, evaluating and managing risks. Control points are implemented throughout the value chain to ensure the safety of processed milk.

Chilled dairy products are sent to distributors in refrigerated lorries to respect the cold chain. In stores, distributors carry out controls in-house to check that the products are being stored well at the right temperature and that good hygiene practices are being used.

Find out more...

Little labels that say a lot

Labels provide information on the nutritional content and origins of dairy products.

For example:

Nutritional labelling for 2016

Optional up until now, seven labelling items will be compulsory under new European regulation. These are: calories, fat, saturated fat, carbohydrates, protein and salt.