French law of 29 June 1934

French law (29 June 1934) bans the addition of any other fat.

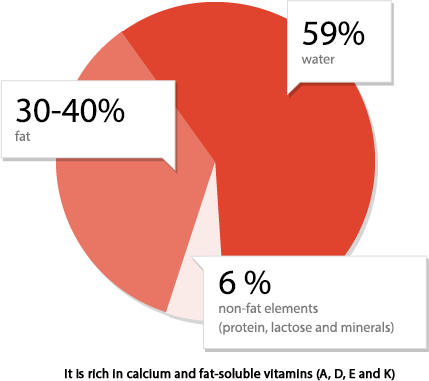

According to current regulation (decree of 23 April 1980), only milk containing at least 30% fat can be labelled “cream”.

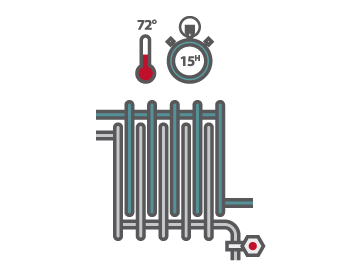

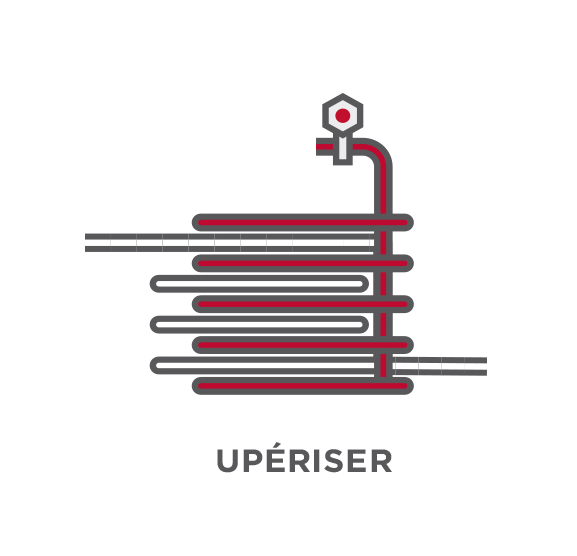

Milk containing 12-30 g of fat per 100 g can use the label “low-fat cream”. Cream and low-fat cream always undergo heat treatment (pasteurization or sterilization), with the exception of raw cream.

“Fresh cream” or “low-fat fresh cream” applies to cream that is pasteurized and then packaged on the production site within 24 hours. These labels therefore cannot be used for sterilized creams.

When cream or low-fat cream contains authorized added products, the fat content is calculated on the dairy ingredients.

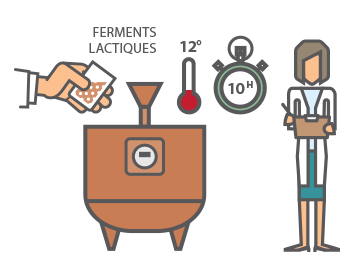

Legislation authorizes the addition of very small quantities of certain products to cream: sucrose (up to 15%), lactic acid fermenting bacteria and stabilizers (0.5%).

The label “fresh cream” means that the cream has been pasteurized: there is no obligation to mark “pasteurized”. Sterilized creams cannot be called “fresh cream”.

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,… All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.