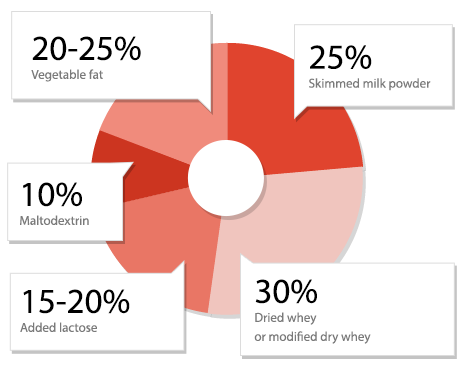

The term “milk” is usually only authorized for products made entirely from cow’s milk protein, but the protein content of “baby milk powder” as it is known in France (“poudre de lait infantile”) varies between manufacturers and for different aged babies.

France is Europe’s largest producer of baby formula, followed by Germany.

It is also a major exporter, exporting more than 134,000 tonnes in 2013. This figure has been steadily rising for five years.

In 2013, 69% of French exports of baby formula are to countries outside Europe. Strong demand for China, in particular is one of the main drivers of this growth.

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,… All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.