"Butter" is a legally protected name

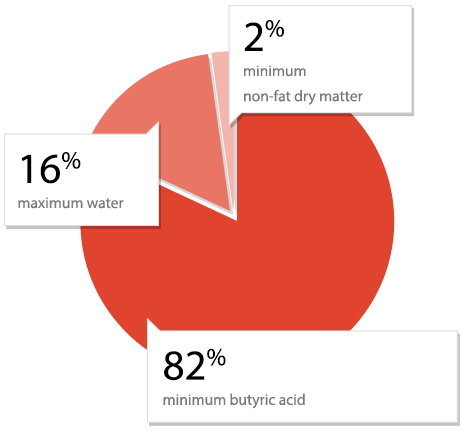

This protection is stipulated in France by decree (30 December 1988) and in the European Union through “Single CMO” regulation (n°1234/2007).

“Butter” may only be used to describe the water-in-fat emulsion product obtained by physically transforming dairy ingredients.

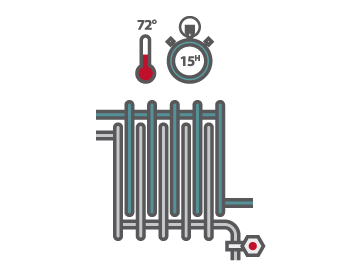

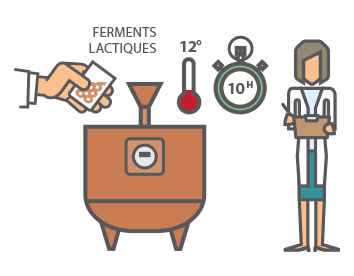

It is made from creams that may be pasteurized, frozen or deep frozen. The 1988 French decree regulates product names, cream processing, and the ingredients of butter and dairy specialities.

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,… All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.