Milk: a source of economic wealth and nutritional health

Milk: a source of economic wealth and nutritional health

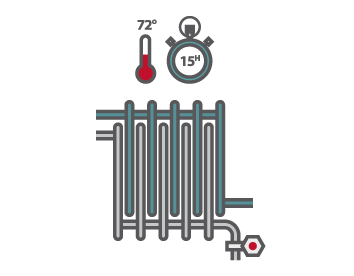

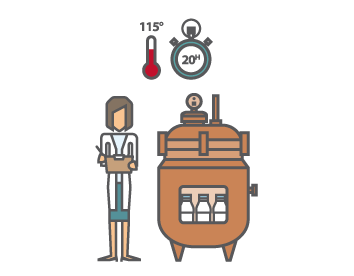

Different types of drinking milk are a key driver of the French economy: 3.3 billion litres were packaged in 2015, or 11% of the milk collected in France. As a fragile, live raw material, milk follows a precise, regulated process to guarantee its bacteriological quality.

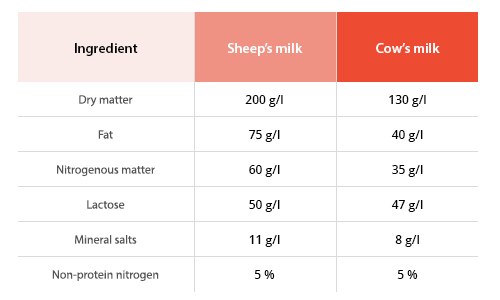

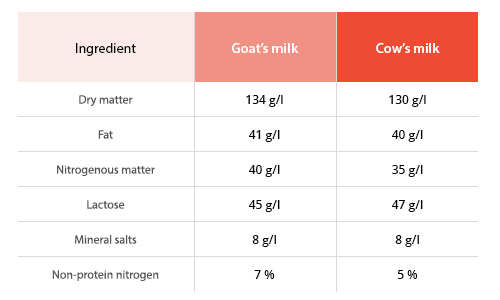

Drinking milk is generally cow’s milk. It also comes from other animals, such as goats and sheep.

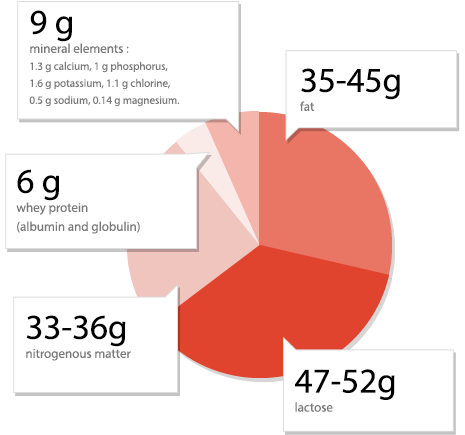

Milk is healthy, and not just because of its calcium. It contains a unique combination of nutrients that are essential to good health throughout our lives!

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,… All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.