Schéma 4 enjeux - ANG

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…Dairy Products website

Everything you need to know about milk and dairy products, the different steps involved in processing them, their diversity and health benefits. Also, practical information such as how to read food labels, make homemade dairy products,…Dairy Products website

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.Cniel Infos website

All about how CNIEL serves the French dairy industry. The organization addresses a wide range of issues, from the dairy economy, international business and promotion, to technology and scientific research. Its work is aimed at helping dairy producers and processors to anticipate market developments and build a strong future.Cniel Infos website

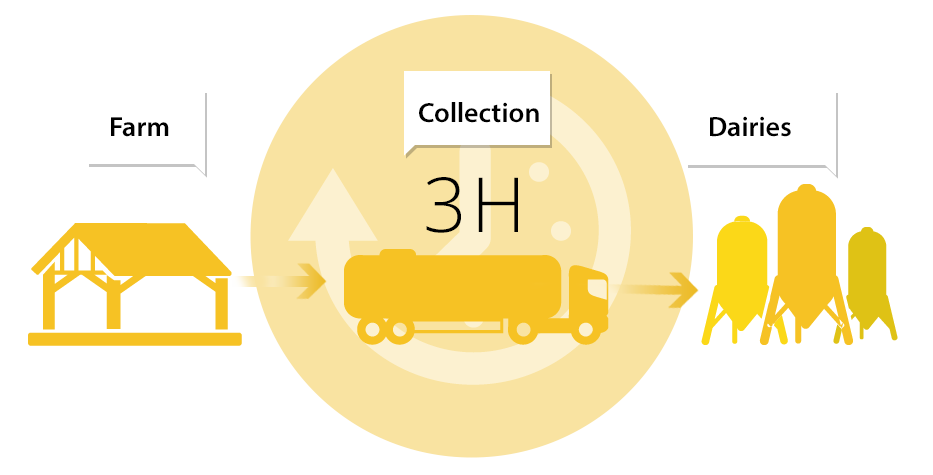

Driven by the shared interest of obtaining milk of the best possible quality, mutually supportive milk processors and producers are organized around milk collection, a critical step in the dairy value chain.

Cows produce milk constantly

On average, 6,800 litres per year with two milking sessions per day. Cows suffer pain if they are not milked.

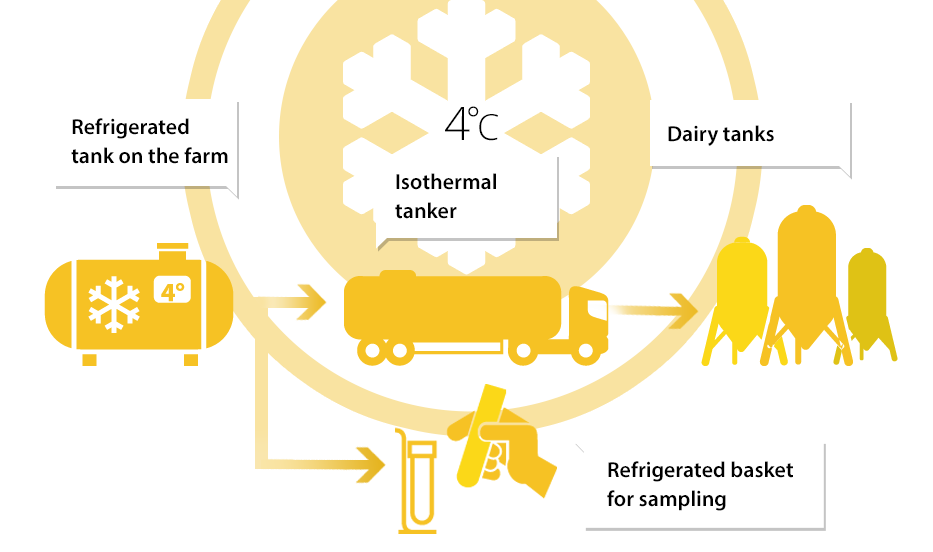

Milk is a perishable raw material

As a live material, milk is fragile and perishable. It must be processed no later than 72 hours after milking.

Farms have limited storage capacity

Milk storage tanks exist in different sizes. When they are full, any remaining milk goes to waste…

Dairies need regular deliveries of milk

to ensure processing continuity.

How is milk collection monitored?

What is monitored?

On average, each milk collection round involves:

Streamlined milk collection rounds save time and fuel.

Some companies use IT tools to optimize rounds.

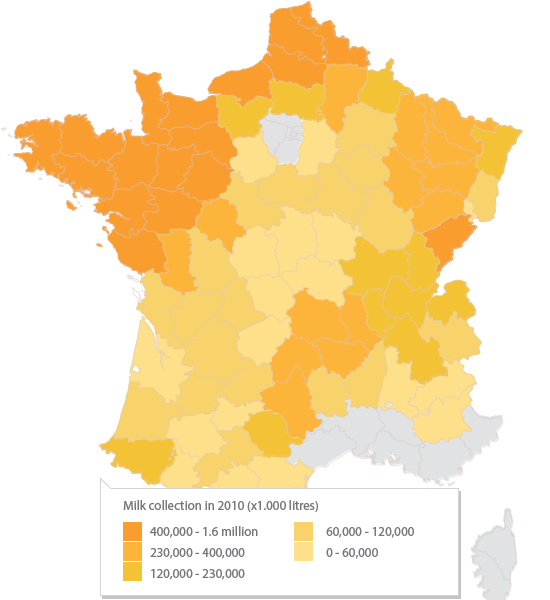

Map of cow’s milk collection in France in 2011